Engineering Services

Integrated engineering solutions translating analysis into practical performance improvements.

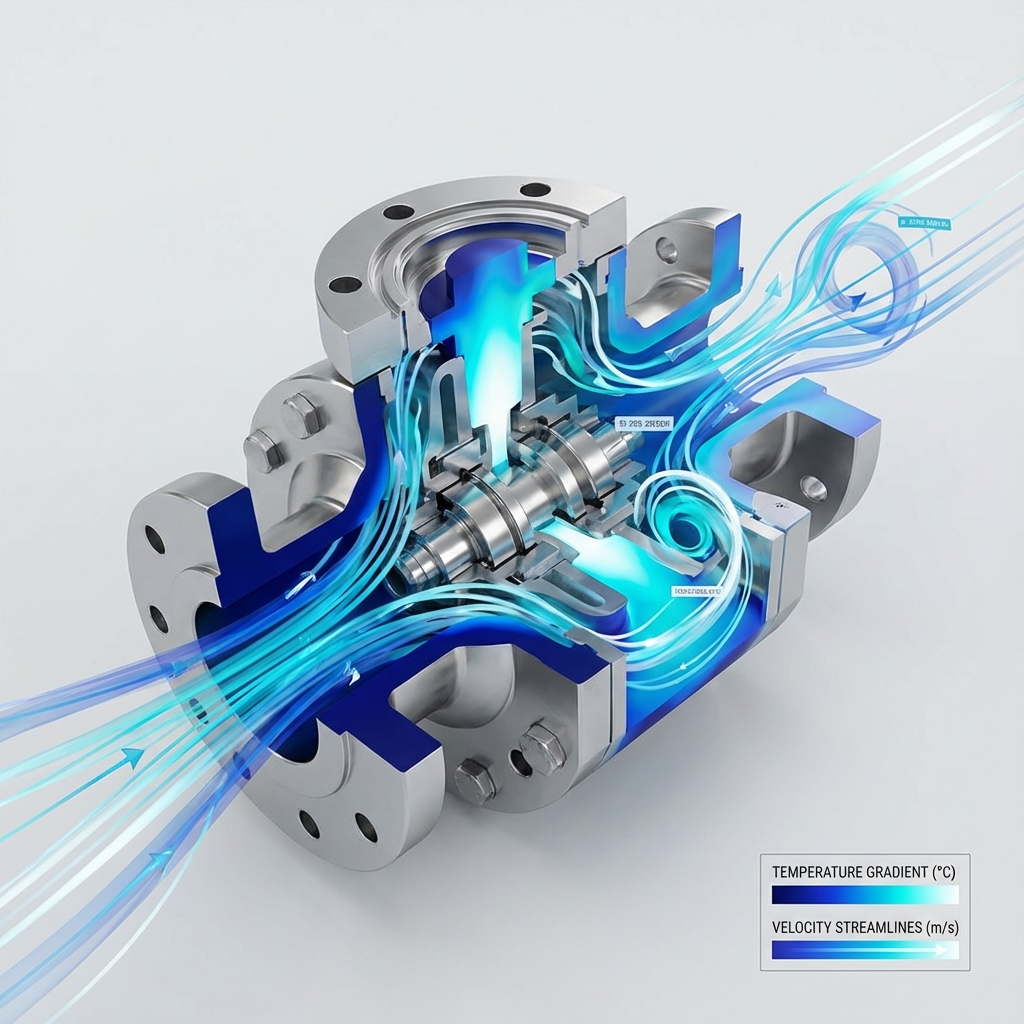

CFD & FEA Engineering Consulting

We provide CFD and FEA engineering consulting as integrated engineering decision tools, closely aligned with product and system design. Our focus is on translating analysis results into practical improvements in performance, durability and manufacturability.

CFD is used to analyze and optimize flow and thermal behavior at both component and system level, while FEA supports structural reliability and design validation under real operating conditions.

Capabilities

- Compressor valve and internal flow analysis

- Thermal flow, heat transfer and cooling performance

- Airflow and enclosure behavior

- Heat exchanger flow and thermal effectiveness

- Structural integrity, deformation and safety margins

- Fatigue assessment and life estimation

- All analyses are guided by application-specific operating conditions, rather than generic assumptions.

What This Service Delivers

- Performance-oriented design decisions

- Reduced development risk before prototyping

- Clear engineering justification for design choices

- Analysis results that directly support hardware improvements

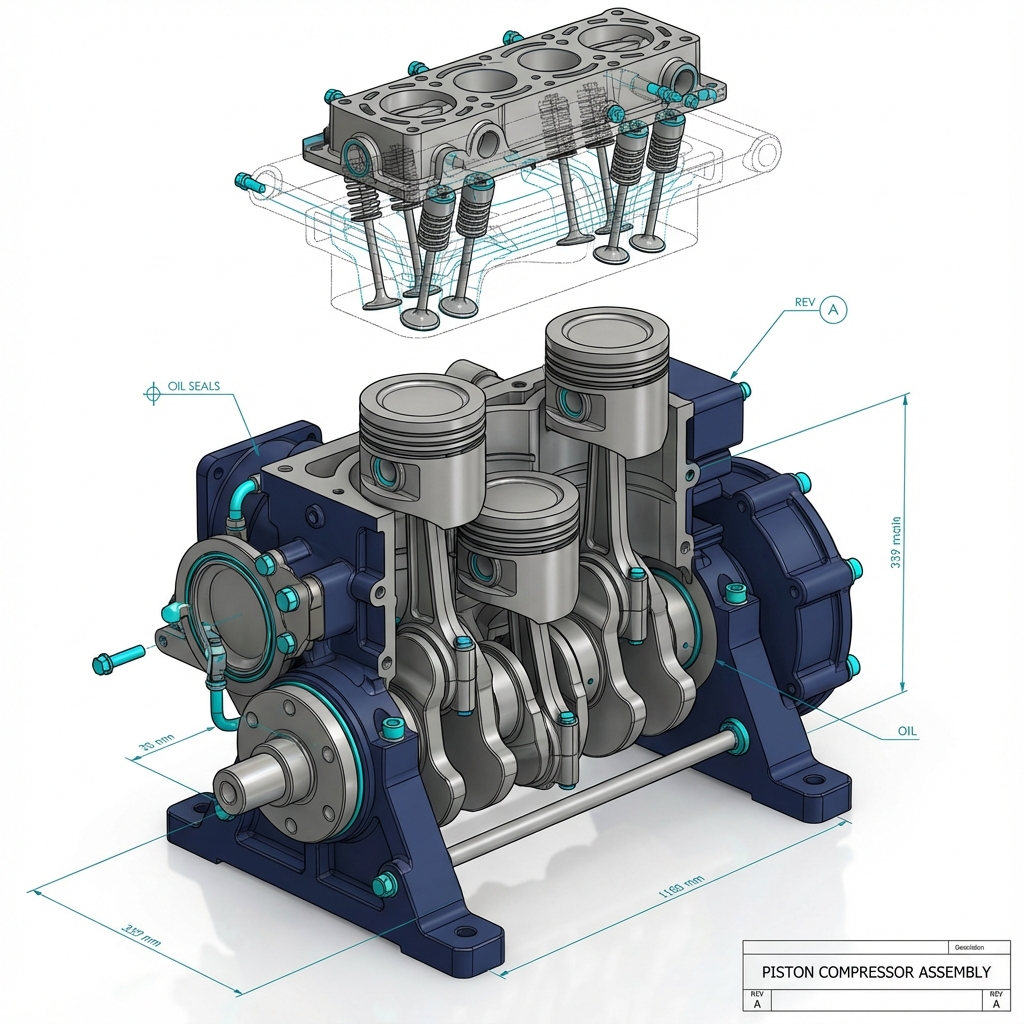

Engineering Product Design Services

From concept to manufacturable hardware. We provide mechanical product design services focused on industrial equipment where performance, reliability and manufacturability must be addressed together.

Our approach goes beyond geometry creation and covers functional design, mechanical integrity and real-world operating constraints, ensuring designs are ready for manufacturing and testing.

Key Design Areas

- Piston compressor & valve system design: Compressor valve development, flow-oriented valve geometry and dynamic behavior

- Mechanical system design: Piston–crank mechanisms, rotating components and structural parts

- Lubrication & sealing concepts: Oil distribution strategies, bearing interfaces and sealing solutions

- Prototype-oriented CAD design: Designs prepared for manufacturing, assembly and testing

Design Philosophy

- Function-driven design with a strong design-for-manufacturing focus

- Integrated with CFD, FEA and engineering calculations

- Suitable for prototype and pilot-scale development

- The objective is to deliver designs that can be built, tested and iterated with confidence.

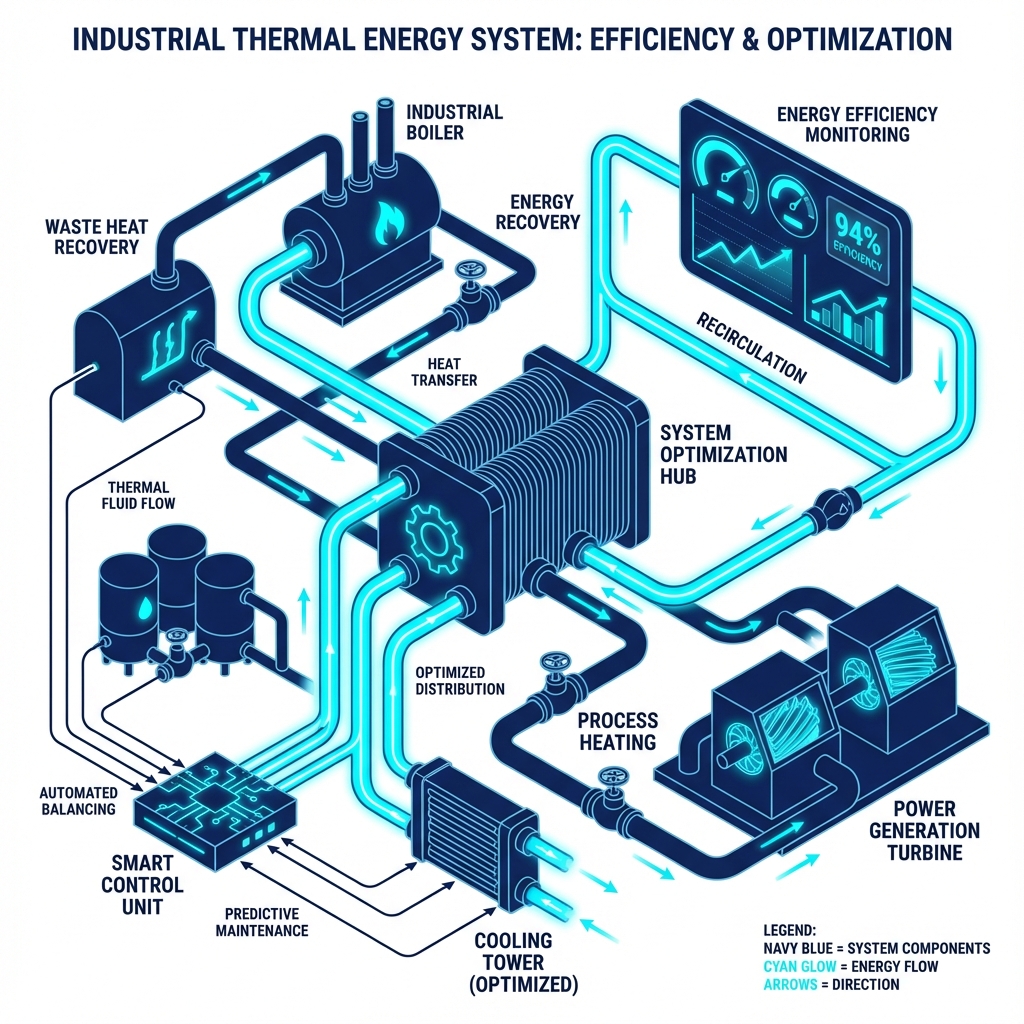

System Design & Energy Efficiency Consulting

We provide energy efficiency and system-level engineering consulting for industrial and building-scale thermal processes.

Our focus is on understanding overall system behavior and identifying practical efficiency improvement opportunities through thermodynamic analysis and engineering insight.

Scope of Service

- Energy efficiency assessment and optimization at system level

- Thermal system and waste heat valorization concept development

- Process-level analysis and operating envelope definition

- 1D thermodynamic modeling for performance estimation and scenario comparison

What This Service Delivers

- Clear insight into energy efficiency potential

- Data-supported engineering recommendations

- Reduced uncertainty in early-stage decisions